-

Insulated Power Cable

-

Flexible Power Cable

-

Armoured Power Cable

-

Coaxial Power Cable

-

Solar Panel Power Cable

-

Electrical Building Wire

-

PVC Flat Cable

-

Bare Ethernet Cable

-

Fire Resistant Cables

-

Copper Clad Aluminum Wire

-

FTTH Fiber Optic Cable

-

Fiber Optic Patch Cord

-

Speaker Wire Cable

-

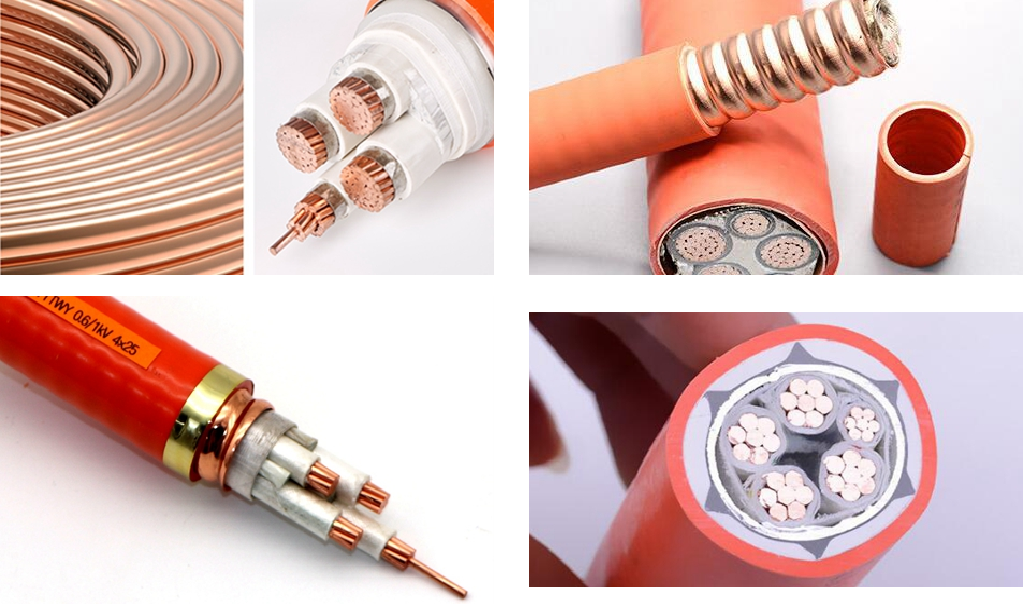

Mineral Insulated Cable

-

Bare Conductor Cable

-

RoseThis mutual cooperation last for about 4 years,and must admit the service they provide is aboved expected. Our cooperation will last for many years.

RoseThis mutual cooperation last for about 4 years,and must admit the service they provide is aboved expected. Our cooperation will last for many years.

BTLY 1.5-6mm2 Mi Heating Cable

| Place of Origin | Jiangsu China |

|---|---|

| Brand Name | Jiangnan |

| Certification | CE,CCC,SABS,TUV,RoHS |

| Model Number | BTLY |

| Minimum Order Quantity | 1000 Meters |

| Price | $0.28/meter |

| Packaging Details | Customized logo(Min. order 10000 meters) Customized packaging(Min. order 10000 meters) Graphic customization(Min. order 10000 meters) |

| Supply Ability | 50000meters<7days |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | BTLY | Application | Tunnels, Cable Trenches, Bridges |

|---|---|---|---|

| Conductor Type | Solid | Brand | Jiangnan |

| Color | Customer's Requirement | Type | Insulated, Fireproof Cable |

| Conductor Material | Copper | Insulation Material | PVC |

| Conductor | Copper | Keyword | Fireproof Cable,BBTRZ, Mineral Fire-proof Cable |

| Place Of Origin | Jiangsu,China | Sheath | PVC |

| Highlight | 6mm2 mi heating cable,6mm2 micc wire |

||

Explosion-proof characteristics: Since mineral insulated cables use metal sheaths as protective layers, flammable gases, oil vapors, and flames cannot reach the electrical equipment connected to the cables, so the cables have explosion-proof characteristics.

Corrosion resistance: Since copper has good corrosion resistance, it does not need any additional protection under normal use environment. Add a layer of PVC outer sheath, so the cable has good corrosion resistance.

2. Resistance to mechanical damage, long life, halogen-free and non-toxic

Resistance to mechanical damage: Since the metal sheath of the cable has certain strength and toughness, the relative position between the core wires and between the core wires and the sheath remains unchanged when the cable is subjected to deformation such as bending, flattening, and torsion. There will be no short circuit and no impact on electrical performance.

Long service life: Since the materials used in the cable are all inorganic materials, they will not age. Its service life can be calculated according to the rate of oxidation and corrosion of the copper sheath. According to the data, it takes 257 years for the sheath to oxidize 0.25mm at an ambient temperature of 250°C, while the thickness of the sheath of mineral insulated cables is generally between 0.34-1.05, and the operating temperature is lower than 250°C, so the cable has Features of long life.

Halogen-free and non-toxic: Since the cables are all composed of inorganic substances (metal copper and mineral insulating layer), even if they are burned at a high temperature of 1000°C, they will not produce smoke, halogen and toxic gases. It is truly halogen-free and non-toxic cable.

3. Overload resistance, copper sheath can be used as grounding wire

Overload resistance: Since the melting point of copper is 1083°C and the mineral insulating layer is also above 1000°C, compared with ordinary plastic cables, the carrying capacity of mineral insulated cables can be increased by a section level, and at the same time, it can withstand considerable overload. The capacity can reach more than 10 times the normal carrying capacity.

The copper sheath can be used as a grounding wire: for mineral insulated cables, due to the continuity and extremely low grounding resistance of the copper sheath, it can be used as a grounding wire and does not require an independent grounding wire.

Mineral insulated flexible fire-resistant cables can be delivered in a complete package without joints according to the needs of users, covering almost all types of cables such as power cables and control cables.

Easy to install

Due to the combination of mineral insulated flexible fire-resistant cables and traditional cable production technology, the installation and laying of cables is more convenient, and the terminal problems often encountered in mineral insulated cables (BTTZ) are avoided.

Small line loss, high carrying capacity

Compared with cables of the same cross-section, mineral insulated flexible fire-resistant cables can transmit higher current than other types of cables and can withstand considerable overload. If the rated current is the same, the line loss is smaller than other cables.

Energy saving and environmental protection

The working temperature of mineral insulated flexible fire-resistant cables is lower than that of other types of cables, so the line loss is low during work, reducing energy waste, and the cable material is inorganic, which can meet the requirements of environmental protection.

High radiation safety

Inorganic materials used in mineral insulated flexible fire-resistant cables, resistant to radiation. It can ensure that the cable has the characteristics of long-term stability, long life and durability.

Explosion-proof performance

The highly compacted insulating material in the cable and the absence of intermediate joints can prevent steam, gas and flame from entering the electrical equipment connected to the cable, so it is suitable for the connection of places with explosion hazards and various explosion-proof equipment and equipment.

Products advantages

Since all the materials of this cable are inorganic materials, it has some advantages that other cables cannot have.

1. Refractory

The two materials copper and mineral insulation used in mineral insulated cables are inorganic. This kind of cable will not burn or support combustion, and can continue to operate under conditions close to flames. The copper sheath melts at 1083°C.

2. High operating temperature

Mineral insulated cables can withstand continuous operating temperatures up to 250°C. And, in an emergency, the cable can continue to operate for a short time at a temperature close to the melting point of the copper sheath.

3. Long life

Inorganic materials used in mineral insulated cables to ensure the stability, long life and fire resistance of the cables.

4. Explosion-proof

The highly compacted insulation in mineral insulated cables prevents the passage of vapors, gases and flames between parts of equipment to which the cable is connected.

5. Small outer diameter

Mineral insulated cables have a smaller diameter than other cables with the same current rating.

6. Waterproof

With its seamless metal sheath, MI cables continue to operate if fully submerged in water.

7. High mechanical strength

Mineral insulated cables are robust and can withstand severe mechanical damage without compromising their electrical properties.